Designing Your Project

Engineering design is necessary when an item cannot be bought "off the shelf". And frankly, if it can be purchased "off the shelf" and simply installed, that is precisely what we recommend: we have zero interest in any project that will not benefit to our clients.

Good design is the versatile use of many fields of knowledge. All too often with other companies designs are flawed in ways that the designer and client alike lacked the experience to avoid. Automated machines are, for example, built in a facility and that facility has a certain weather type and the machine works well under those conditions. The client then finds the equipment glitchy for "no apparent reason" in the cold winter months. Or the designer has never worked on an assembly line and so does not account for the realistic level of maintenance which will actually occur with the real world shifts of man-power and training. Again, the machines fail pre-maturely costing the client a loss in untold profits. These designers may not "feel" it is their fault, but that is small consolation to the client who had invested in them.

The knowledge, judgment and experience of the lead designer on a project will usually make or break the project. In a world where you must adapt to survive you need an experienced proven master that can cross platforms of technology like they are old friends, team mates even. It comes down to the mastery of the individuals involved.

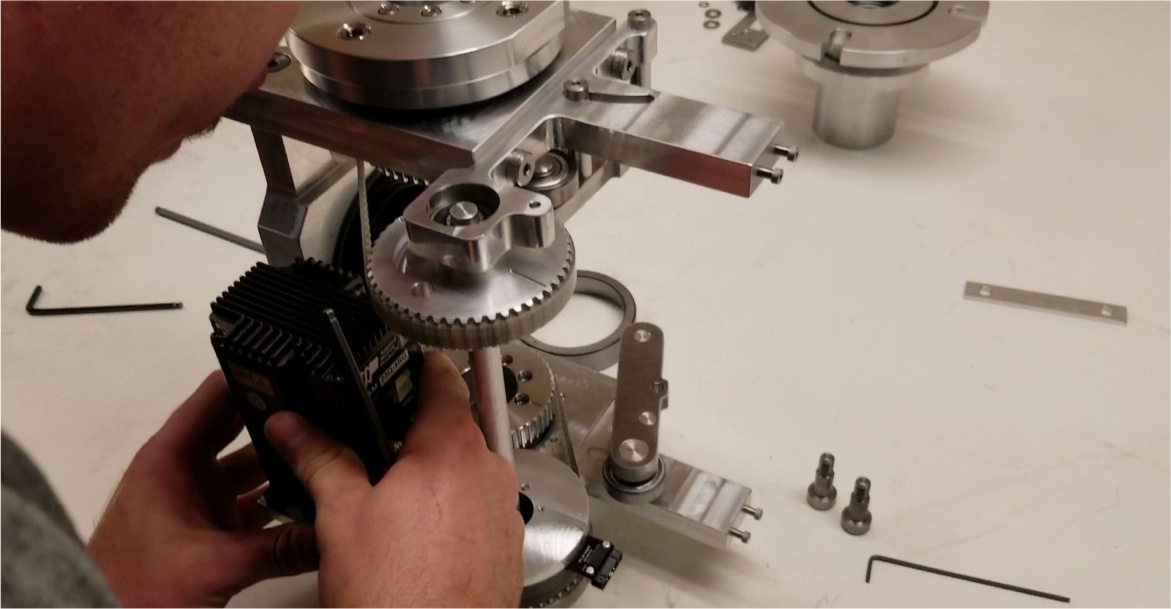

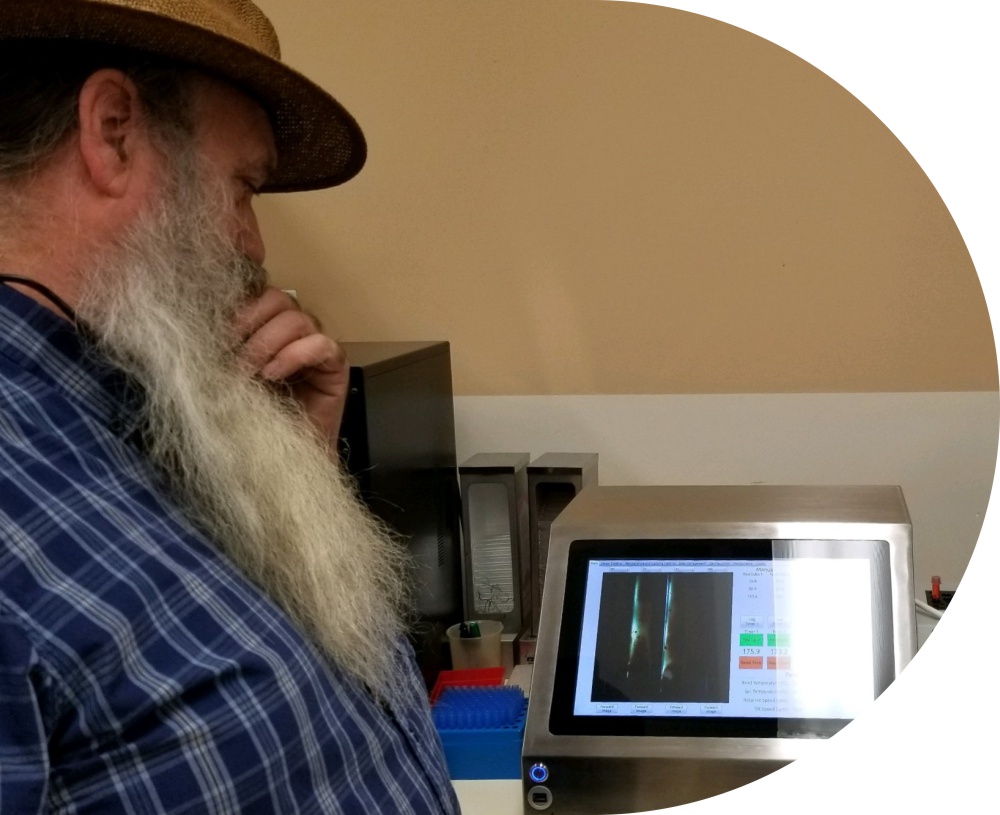

As your lead engineer, John Wetteland offers his over 30 years experience working professionally in the automation engineering field and an even longer mechanical background. It becomes almost absurd to list the fields and areas he has serviced from aircraft and automotive, to theme parks and assembly lines. He can blend old and new technologies and get the most out of each while many others are still scratching their heads. Which technology is best for a medical device made to locate a disease? Is it infrared, sonar pulses, temperature? Speaking of temperature did anyone consider the temperature from the amount of light required to punch through a blood sample and regulating the temperature tolerances to properly measure (among other things) how fast the blood sample of the patient will coagulate? And can the machine do all this fast enough to give a surgeon hard medical data for the patient they are currently doing a liver transplant on? Yes. With certainty we say yes, because this is not an entirely theoretical example. The above is in reference to a machine actually built by JW Automation Consulting and Design for a leading university's medical section. And, who knows, that blood analysis machine may one day save the life of someone you know.

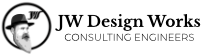

Pneumatic, hydraulic, electrics and electronics, motion control, computer vision and other machine learning? We got you covered. Large equipment experience, fine control experience (like that tool we designed for the aircraft industry accurate within 50 millionths of an inch. Yes, really. And oh by the way, that knowledge then comes in handy when designing a precise medical device). Whether you're a defense contractor needing a heavy duty piece of motorized equipment for border security or are a major automotive corporation needing assistance design an electric engine for a future model car, we stand ready to assist you in achieving or exceeding the precision of your specs and have no qualms in saying so.